Flood of FDI

2017-12-25

China Daily

This Christmas, it appears as if Santa Claus has unfolded a big bagful of FDI, or foreign direct investment, in China.

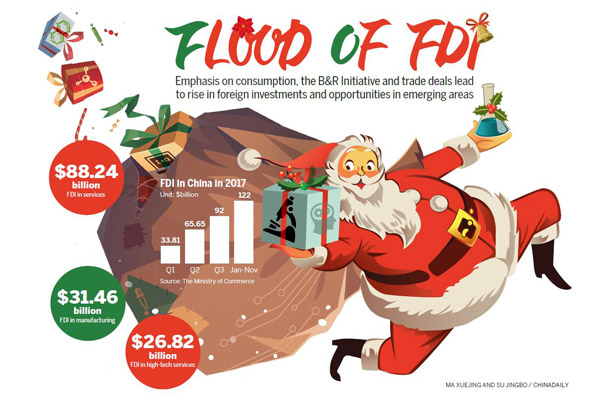

The October-December quarter will likely see robust year-on-year growth in FDI. In the January-November period, FDI in China rose 9.8 percent year-on-year to reach 803.62 billion yuan ($122 billion).

That marks a dramatic improvement in one month because in the January-October period, the year-on-year increase in FDI was 1.9 percent, according to data from the Ministry of Commerce.

The Chinese government’s emphasis on boosting FDI in high-end manufacturing, services and environment-themed businesses as part of its larger strategy to restructure and transform the economy, seems to be paying off.

China, which has sworn by the policy of full-fledged opening-up, will open the door wider to foreign investors in areas such as financial services, manufacturing and services. The government will lower barriers to market access in some key areas in an orderly way, said Gao Feng, spokesman for the Ministry of Commerce.

The efforts are in line with the goals of the digital-age economic reforms that were underlined at the annual Central Economic Work Conference last week.

Global companies such as BASF SE, Emerson Electric Co, Starbucks Corp and Air Asia have taken the FDI route to expand their play in the Chinese mainland.

“Many of these opportunities come from the country’s growing demand for consumption-related products and services, diversified market channels created by the Belt and Road Initiative and free trade deals with partner countries. Opportunities are also arising from the hunger for more homemade sophisticated industrial products,” said Gao.

Thanks to the government’s resolve to attract more foreign capital this year, segments newly identified as key to sustained growth-automation, digitalization, financial services, healthcare, aviation, environmental technologies and renewable energy businesses-are all expected to benefit.

For instance, German chemical giant BASF kicked off production at its 140 million euros ($164.53 million) automotive coatings facility in Shanghai.

Late November, it had announced start of operations at its major chemical catalyst manufacturing plant in Shanghai.

The coatings project is an extension of the company’s existing 50 million euros automotive coatings plant, a joint venture between BASF and Shanghai Huayi Fine Chemical Co.

It will further enhance the company’s local production and better serve the growing automotive market in China and the Asia-Pacific, according to the company.

The new plant produces thinners, primers, clear coats and waterborne base coats, which will be supported by the BASF Innovation Campus Asia Pacific in Shanghai, a new automotive application center.

By the end of 2018, the center will provide automotive manufacturers access to advanced research and development facilities. These include a 3-D robot for coating applications.

“The global automotive market is expected to continue to grow significantly, with China as the biggest driver. The inauguration of this new plant in Shanghai will help us to support the growth of our customers and take an active role in developing the automotive market in China,” said Dirk Bremm, president of BASF’s coatings division.

In 2016, a total of 48.6 million light vehicle units were produced in the Asia-Pacific region, accounting for 52 percent of global production.

China made 28.12 million of them and sold 28.03 million cars in 2016, up 14.5 percent and 13.7 percent respectively.

That marked the eighth year in a row for China as the world’s largest automobile market, according to data from the China Association of Automobile Manufacturers.

Automotive sector in not the only sector that saw a spike in FDI this year.

In July, the Chinese government eased entry restrictions and share ratio limitations on foreign investment in areas such as nurseries and elderly care, architecture, accounting, commerce, logistics, e-commerce and the traditional manufacturing and services sectors.

It also urged mega cities like Beijing, Shanghai, Guangzhou and Shenzhen to take the lead in improving the business environment, calling for moves to reduce inspections and fines on companies, and ban the charging of illegal fees.

Foreign companies this year are also entitled to participate in bidding for government procurement contracts, as long as their products are made in China. The government will also allow them to go public and issue bonds in local markets to diversify financing channels.

“Because of rising labor costs and weak global market demand, China is veering toward growth reliant on domestic consumption rather than exports,” said Feng Yaoxiang, a spokesman for Beijing-based China Council for the Promotion of International Trade.

“Companies from Europe, Japan and the United States therefore have already discovered that it is time to invest more in Chinese research and development, as well as its science and technology and design businesses,” said Feng. “New growth points are expected to present themselves as the economy becomes more sophisticated.”

The US-based Emerson Electric Co opened a new measurement technology center in Beijing on Nov 14 to serve its automation solutions business in China and across Asia.

The facility, which brought in FDI of $28 million, includes the company’s first China solutions center for customers and a newly built manufacturing plant to meet domestic and Asia-Pacific market demand. This plant has since been expanded.

Agreed Gao Peiyong, director of the Institute of Economics at the Chinese Academy of Social Sciences in Beijing.

The Ministry of Commerce has repeatedly said that “because of its huge market size, industrial infrastructure foundation and logistics network, China is, in the long term, the most attractive market for global companies”.

China’s key areas for economic reform and industrial upgrading will grow into new investment opportunities for many German companies, said Alexandra Voss, a member of the all-China board of the German Chamber of Commerce.

British oil major BP PLC also announced plans earlier this month to build a new lubricants blending plant in China to produce high-quality lubricants. The new plant will be BP’s third lubricants blending facility in China and will see investment of around $230 million.

“Premium lubricants are a growth business for BP and ensuring that we can meet demand in a country growing as quickly as China is essential to our success,” said Tufan Erginbilgic, BP Downstream’s chief executive officer.

The new plant, which is expected to start operations before the end of 2021, will have an annual production capacity of 200,000 metric tons.